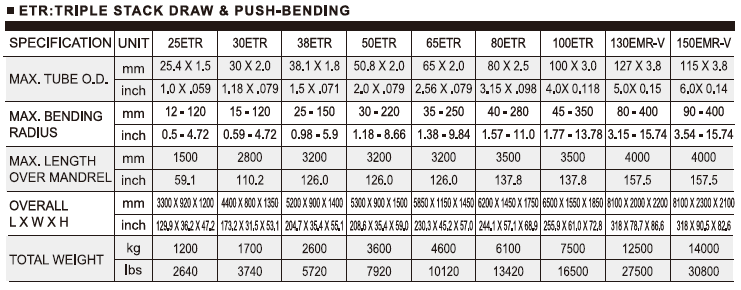

UTE Alpine 50ETR Hybrid Triple Stack CNC Bender

The Alpine ETR Series CNC bending machines feature touch screen controllers, a triple stack tooling design with 4 axes (Y- Feeding, B-Rotation, C-Bending, X- Horizontal with horizontal bend head shifting for tooling changing) and are driven by an A/C servo motor. The ETR Series tube benders equip both draw-bending & push-bending function in the same tool stack. The electric-driven rotary draw bending arm performs with high accuracy and reduced electrical consumption. Alpine machines also feature a patented planetary gear driven bending head. This patented bending head has a compact and rigid design that provides highly accurate bending results and at the same time minimized machine interference. The planetary gears in the bend head also provide speed reduction and high torque transmission. These tube benders are perfect for application in the furniture, automotive, motorcycle, fitness equipment, aerospace industries and more.

UTE Alpine Model AB38ETR Shown Above

Standard Machine and Accessories

- Master IV Controller

- PC base 15″ color LCD Touch Screen control — Easy and fast programming

- Right Hand Bending

- ETR — Triple Stack with two Bend die plus one Rolling die

- EBR — Double Stack with one Bend die plus one Rolling die

- ETR: DOB, POB, DBB, BHH 4 Axes are A/C Servo Motor

- Patented Direct drive A/C servo motor bending head — fewest interference area

- Adopts planetary gears assembly as the speed reduction and torque transmission

- Patented Cam-Type shifting system on bending head

- Alternative Rotary Bend and Push Bend

- With arc Curvature to measure and calculate the Radius

- With DBB alternative Repeat Feeding or End Grip function

- Unlimited Program Storage

- With Metric and Inch setting conversion

- XYZ to YBC conversion

- Using parameter to determine simultaneous motion of Y, B & C Axes — the interaction between Y,B,C axis

- Booster Device of Pressure Die (excludes 30 model)

- With Independent programmable speeds Y, B, and C axes (10×8)

- With Air Cooling System

- Automatic Slide-way Lubrication for bend arm to reduce maintenance time

- Foot Pedal Cycle start

- Wiper die Bracket

- 3 Mandrel Rods

- Operation and Maintenance Manual

- Tool Box with Adjusted Tools

- Electric: As required (3 phase 208V or 220V or 480V)

Available Upgrade Options:

- AMRU — Anticipate Mandrel Retraction Unit

- AML — Auto Mandrel Lubrication

- Dynamic Visual Simulation Software — Collision Protection

- Safety Mat Connection Ready (without CE Mark)

- CE Mark

- Safety Mat

- Safety Scanner

- Free Standing Pedestal — The foot pedal is replaced by a free standing pedestal

- ERB — Rear Booster Device (50 and above model)